If you are a woodworker or a DIY enthusiast, you might require a practical table saw. Indeed, a table saw is the heart of a craftsmen’s collection as you work with it a lot. This table saw buying guide contains information about the equipment’s essential features, how it works, and what features to look for before purchasing.

A table saw is nothing but a circular saw placed under a table surface. The table saw blade protrudes above the table where it lies exposed and cuts wood. The exposed portion allows the table saw to have a continual cutting apparatus. It lets the users place workpieces into the blade in a measurable and controllable manner.

Table saw helps in making cuts on wood precisely and accurately. The blade bulges through the table saw and provides support to the material, usually wood. In modern table saws, you can change the cut depth by moving the blade up and down.

The three main cut types that it makes are crosscut, ripping cut, and dado cut. You can make a crosscut against the board’s narrow grain. A ripping cut involves a cut along the board’s length. A dado cut is a flat-bottom and square-walled channel cut across wood’s grain.

It is a groove cut that fits a wood piece into another. It allows for whole box joints. The table saw is no less than the woodshop’s workhorse. Aside from its use to rip material to the desired width, it has a wide array of jigs and accessories to make different cut types.

It is probably the most productive and versatile among all the woodworking machines to make cuts professionally. The tool can crosscut, square, miter-cut, rabbet, and apply shapes to wood stock’s edges.

Before reading the guide, think about the work type you wish to do with your saw. Are you going to do home improvement projects or professional woodworking? Will you be cutting plywood sheets or small exotic wood pieces?

What to look for When Buying a Table Saw?

Woodworkers mostly want to ensure accuracy and productivity in cutting. The table saw buying guide gives details of the types of table saws and how each type suits the specific needs.

Consider the Table Saw Type that Suits Your Needs

Portable Table Saw

The portable table saw is lighter and smaller as it is designed to be mobile. There is less use of heavier and more rigid materials to reduce the weight. Mostly, portable table saws have a direct drive 15-amp and 120V motors that do not produce more than 2 HP.

The three main types include Jobsite, compact, and benchtop table saws.

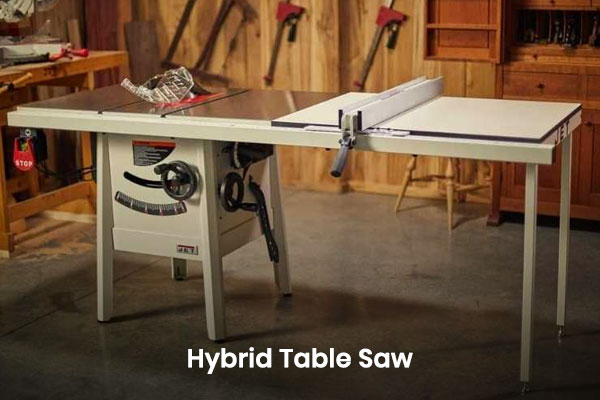

Hybrid Table Saw

The hybrid saw lies somewhere between the power and size of a contractor table saw, and the updated technology of a cabinet table saw. It offers belt-drive motors at an affordable price with long-term reliability.

A hybrid table saw lets you make very accurate cuts, thanks to the low vibration motor. It is as powerful as a cabinet table saw. The hybrid table saw handles large furniture construction jobs. The common application of hybrid table saw is woodworking jobs of all sizes and shapes and large home repair projects. It is also used in construction jobs that include specific and detailed jobs.

Benchtop Table Saw

As the name suggests, you place these saws on a table saw workbench. The benchtop table saw is compact, lightweight, and affordable. It does not have a stand or transport wheels and is portable because of its lesser weight. It mainly relies on the use of lightweight materials like aluminum, plastic, and other composite materials.

The benchtop table saw is easy to set up and reasonably priced. It is mainly used in building small furniture setups like coffee tables, dog houses, and chairs. Benchtop saw has application in minor construction projects like decorative woodworking, installing small pipes, and arts and crafts.

Contractor Table Saw

The contractor table saw comes with new hardware technology. It is smaller in size with a powerful motor, making it heavier. The outboard motor demands longer belts that increase the vibrations produced.

Contractor saws are less expensive cabinet saws and more powerful than new portable models. They help in professional woodworking that includes construction, carpentry, and medium to large building projects. The contractor saw it has application in small, medium, and large DIY and home improvement projects.

Cabinet Table saw

The most powerful of all the table saw types is the cabinet saw. Each part of a cabinet saw is durable and robust to withstand heavy-duty use. A cabinet saw is precise, bulky, and heavy and promises to last long. The motors are powerful, run on 240V and produce between 3hp-5hp.

The weight is often more than 500 pounds, with massive tables that enhance the device’s stability. Cabinet table saw is an ideal combination of power, accuracy, and incredible rip capacity.

The cabinet saw is highly used in a large construction or woodworking projects. It is applied in professional furniture making of all sizes, cuts that require precision, and milling boards. A variation of the traditional cabinet type is a sliding table saw. It is mostly used for cutting large panels and sheet goods like MDF or plywood.

So, different types of table saws serve different purposes. They are of different sizes and weights. You have to decide the table saw type that will suit your needs before making a final purchase. You can consider the above table saw basics for choosing a device.

For basic DIY projects or decorative trim work, a smaller and portable table saw will be affordable and convenient. Hobbyists and DIY enthusiasts can go for contractor saws. It can be a less expensive and more powerful option.

You will need more extensive, sturdy, and robust table saws for professional and large construction and furniture building projects.

Consider Certain Features to Choose the Table Saw for You

You need to know the table saw’s specific features to help you choose the best table saw that suits your needs. The table saw buying guide includes all the particular characteristics so that you do not overlook them.

Don’t Forget the Basic and Other Features

Let us now look at the noticeable features of the table saw.

Miter Gauge

A miter gauge is a device that holds workpieces at a set angle while they are cut on a table saw. It slides forth and back in miter slots running parallel to the blade, mainly on either side. It helps to push the material safely through the edge.

It is an essential component of the table saw for making cross and angled cuts. You have to hold the miter gauge and workpiece together by hand and move across the worktable to cut.

The miter gauge holds the material at a specific angle to make a precise cut. The locking mechanism hinges from 45 to -45 degrees and slides into a miter slot. However, the miter slot is not proprietary; instead, it is standard.

Look out for a good quality miter gauge, a miter gauge that fits tightly in the slots without the slightest tremble and slides easily. The head should be marked accurately and set securely at an angle to dial in the exact angle.

Blade Option

The blades in table saws have different diameters, speeds, number of teeth, materials, arbor, and kerf sizes. All these have an impact on their specific applications. Blades of portable table saws have a standard diameter of 10 inches, ranging from 5-12 inches in some models.

A 10″ blade diameter gives you around 3-1/2″ cut capacity at 90 degrees. The number of teeth may vary from 24-80, while the materials include carbon, carbide, and diamond. The portable table saws for home use might also have carbide-tipped blades.

Motor Type

A table saw has two motor types.

Direct-Drive

This motor configuration is primarily found in the portable table saw range. Direct-drive motors are those in which the blade is attached to the motor directly, which turns it. They are smaller, quieter, and less powerful, which produces less vibration.

Since the direct-drive motor does not have a belt to replace, it requires lesser maintenance. It is cheaper and exhibits higher efficiency.

Belt-Drive

A belt-drive table saw drives the blade by a pulley-driven v-belt. The belt is attached to the motor that produces more power and torque. The motor type is commonly found in stationary, more giant table saws as it is heavier.

A table saw with a belt-drive motor produces cleaner and accurate cuts, so it is a priority for professionals working in a workshop. It is noisier and creates more vibration.

Rip Capacity

A table saw’s rip capacity is the space between the table saw and the fence’s edge when extended to the maximum. You can increase the rip capacity by extending one of the table’s sides, readjusting the existing fence, or purchasing a table extension.

A portable benchtop and job site table saw have a rip capacity of 28 inches, while the contractor table has a saw 3 inches rip capacity. A cabinet table saw comes with a rip capacity of 50 inches.

There is rarely a need for a ripping capacity of more than 24 inches as it allows the cutting of large sheets easily. However, a 50-inch rip capacity table saw can make a square cut on a plywood sheet, cutting it in half in one chance.

Look into Fence

A standard table saw fence has a rip fence that is parallel to the saw blade. You can adjust the fence to different distances from the blade to set the final cut’s size. It is advisable to place the rip fence on the dominant hand while using the table saw.

It will give you better control and stability during cutting. It is also safer and easier to do.

Horsepower

An engine’s horsepower assists in ripping the material’s larger pieces. The majority of contractor table saws have either an 11/2 or 2 hp motor. Cabinet motors have 3-5hp motors embedded in them.

The induction motor from 3hp -5hp will help in cutting through more significant pieces of material. A saw with a 1-2hp motor will cut through a 2-inch piece of wood. Cutting a larger material requires a higher hp motor.

Magnetic Switches

A professional-grade magnetic switch is protected against thermal overload and shuts down automatically on power interruption. So, a table saw will not start when you turn on the circuits again. It means that a magnetic switch will not just turn on the table saw as the power comes after a failure.

Throat Plate

The metal or plastic throat plates allow easy access to the blades for changing them. A table saw without a throat plate in the wide-open insert of the saw’s top is unsafe to use. Many times, the wide slot does not offer enough support to the wood next to the blade.

As a result, wood splinters out on the bottom while cutting, creating issues in making fine cuts. You can use a zero-clearance throat plate to cut a slot for accommodating the dado blade. The throat plate closes the gap that comes with the saw and reduces the chance of tear-out on the cuts.

Elevation and Cutting Depth

A saw’s lower blade height contains a lower angle. The force that is directed back to you that can be dangerous. It implies that a blade with a lower height will have more teeth in contact with wood. It results in more heat generation while cutting.

A blade with more height has a higher angle of incidence. Here, fewer teeth come in contact with the material and cut faster. It is also cooler, so safer while making cuts.

Consider Important Safety Features

It is essential not to overlook the safety features of a hand tool. The table saw buying guide highlights the critical safety features that you can consider while buying a device.

Anti-kickback pawls

Pawls are spring-loaded arms to prevent kickbacks while working on a table saw. These are mounted behind the blade. The pawls have rear-pointing teeth that allow the workpiece to move forward without resistance through the saw’s blade.

It digs in to prevent the workpiece from flying back in a kickback. It is a critical table saw safety feature, so try looking for quality pawls. They press down with adequate strength to prevent kickbacks.

Splitter and Riving Knife

The splitter and riving knife help provide safety to the operator. A riving knife is superior to a traditional spitter. A riving knife lies behind the blade and moves up and down in alignment with the blade’s height.

The riving knife prevents kickbacks. You can detach or replace it for making a safe cut. You do not need a heavy guard around the table. Instead, you can use a guard that lays alongside the riving knife. However, a traditional splitter sits near the table saw’s back. It does not move with the blade and is at a fixed height. The higher distance of splitter allows for a more significant kickback from the table.

Blade Guard

Blade guard is a pivoting shield that protects you from dust and debris and avoids accidental contact with the blade. It is pretty helpful for professional craftsmen as it safeguards them from the kickback. The blade guard fits over the blade itself. They lock to make the workpiece slide under them and offer the blades a clear view.

Saw Stop Sensor

The saw stop sensor is valuable table saw safety equipment. The sensor detects contact of table saw with skin. The blade has an electrical signal that the safety system monitors continually. When the skin comes in contact with the blade, the signal changes, it is because the human body is conductive.

The signal change activates the safety system. The table saw stops in less than five milliseconds and produces an angular momentum. It retracts the blade into the table. The saw stop sensor prevents major injury to the operator.

Consider the Accessories

The table saw buying guide helps you consider certain accessories in a table saw before buying.

Table extensions

Table extensions offer a great rip capacity and a steady work surface for professionals. It is useful, especially for cutting wider stock. Most table saws allow a table extension to attach to the saw’s right side.

And yes! Look out for flat table extensions as deviated extensions cause inaccurate cuts. Extensions should fit in tightly to the table.

Dust Collection

It is okay not to consider the dust particles that the table saw produces while cutting. However, you need to take care of the nasty particles you breathe when working with the table saw. Smaller saws provide around 2″ or 2 ½” fittings for a typical shop.

The larger saws have 4″ ports for fitting the dust collection system. Contractor models that serve outdoor or Jobsite use have bottoms where sawdust falls out.

Crosscut Sled

The crosscut sled holds the workpiece at a static 90-degree angle to the blade. A runner fastened in a miter slot guides the crosscut sled. It helps in attaining accurate cuts repeatedly. Mostly, trade professionals like cabinet and furniture makers use crosscut sleds.

Table Saw Stands

Rolling table saw stands offer enough portability, especially when you are working on a job site. Their design allows stability in moving them. Hybrid and cabinet table saws weigh around 600lbs, so they are easy to carry. Mobile bases provide an added mobility to the stationary saws around the workshop.

Featherboard

A feather board is a safety device that applies pressure against the workpiece. With this, the material is either flat against the rip or in a similar position in the miter slot and attached with clamps.

Dado Capacity

Dado sets cut a material’s wide slots in a single sweep. These are pretty useful in the woodwork or cabinet-making business. You can find sets in 6″,8″, and 10″ diameters. Various table saws let you stack a dado blade set.

It is among the practical accessories you can buy with a table saw. Ensure to check that the table saw’s arbor is long enough to fit in a dado stack.

Shopping By Brands

If you’re looking for the best table saw, you should remember that it’s not an easy task in any sense. To invest in the best table saw, you first need to understand its key types, i.e., portable & stationary.

When you have finalized what type of table saw suits your purpose, then comes another tricky part. That is, searching for the best brands of the table saw. To help you out with this, here are the top 5 table saws you can consider.

Makita 2705 Table Saw

Makita 2705 is a versatile and powerful table saw for both shops and on-the-job sites. It comes with a high-performance 15 amp motor that delivers around 4,800 RPM. Not to forget its electric brake that guarantees maximum productivity. It comes with a good cutting capacity, i.e., 3-5/8-Inch at 90° and 1-1/2-Inch at 45°. Due to this, you can cut 4x material in one go.

Benefits

- Rip fence slides across the flat table for quick and accurate adjustments.

- The right extension allows a large cutting capacity to cut 4×8 sheets of plywood in a single go.

- Tool-less modular blade guard system with adjustable dual side guards.

- Large on and off switch.

- An easy-to-read scale for fast adjustments.

Rockwell RK7241S Table Saw

This Rockwell RK7241S table saw is a heavy-duty, versatile, and lightweight option for a workshop, job site, or cabinet shop. Due to its lightweight and integrated wheels, the RK7241S is easy to transport from one job site to the next. What separates it from other saws in its class is its cutting depth.

Rockwell has also provided it with a laser indicator for a precise cut. Not to forget about its 10-inch table that allows you to cut bigger plywood pieces in a single go.

Benefits

- Best-in-class cutting depth

- Laser indicator

- Folding fence for broader cuts

- A trolley stand for smooth movements

- Two-year limited warranty

Wen 3720 Table Saw

The Wen 3720 is a 10″ job site table saw with a one-of-a-kind rolling stand for easy movements from one job site to another. Due to its 26″ ripping capacity, it can easily cut boards up to 3-9/16″ deep at 90° and 2-½” deep at 45°.

Its powerful 15A motor rotates 4400 times per minute. This makes it easy to cut even the hardest of woods. There are two table extensions in either direction. Thus, you can expand your workspace to 40 x 35-⅞”.

Benefits

- Sufficient space for larger workpieces

- Beveling blade for accurate angled cuts

- Portable and on-saw tool storage

- Compatible with dado heads

- Adjustment tracking knob to adjust the height and angle of the blade

Hitachi C10RJ Table Saw

Another versatile table saw an option for both job sites and workshops are this Hitachi C10RJ table saw. It features a 15 Amp motor that produces 4,500 RPM. This much power allows it to rip through the toughest woods. Further, Hitachi has also provided the function- soft start to reduce unwanted noise and recoiling while starting up.

From a safety point of view, the table saw is also equipped with an electric brake that halts the rotation of the blade within seconds.

Benefits

- Telescopic table extension

- Bevel range of 0° to 45°

- Oversized power switch with emergency off safety cover

- Robust and stable stand

Dewalt DWE7491RS Table Saw

This robust Dewalt DWE7491RS Table Saw comes with a 32-½” rip capacity, onboard storage system, and 2-½” dust collection port. Its working space is approximately 10″, and you also get a rolling stand for its smooth movements.

Another feature of this Dewalt DWE7491RA table saw is its ability to cut 3-1/8 inches deep at 90° and 2-1/4 inches at 45°.

Benefits

- 10-inch 24-Tooth Carbide Blade

- Ideal for cabinet installers, hardwood floor installers, deck builders, woodworkers, etc.

- Rolling stand

- Large heavy-duty wheels

- Onboard storage system

- Telescopic fence rails

Conclusion

The above guide provides you with complete knowledge of the table saw. Best of all, it will save you time from doing endless research to decide the best table saw that suits your needs. If you have a shop space, a contractor or hybrid saw is enough for carrying almost all hobby or home projects.

The hybrid saw might provide better dust collection techniques than a contractor saw. A benchtop model will suit projects or small workshops that require portability. Professional craftsmen or woodworkers should go for a cabinet table saw.

Before you buy a table saw, read the above buying guide thoroughly. It will review all the features that you should consider while choosing a table saw. I hope the guide arms you with abundant knowledge so you can select an appropriate table saw.

Good luck with your table saw!

If you would like to get reviews of other power tools, kindly visit our Guide page.

Leave a Reply